Our Company

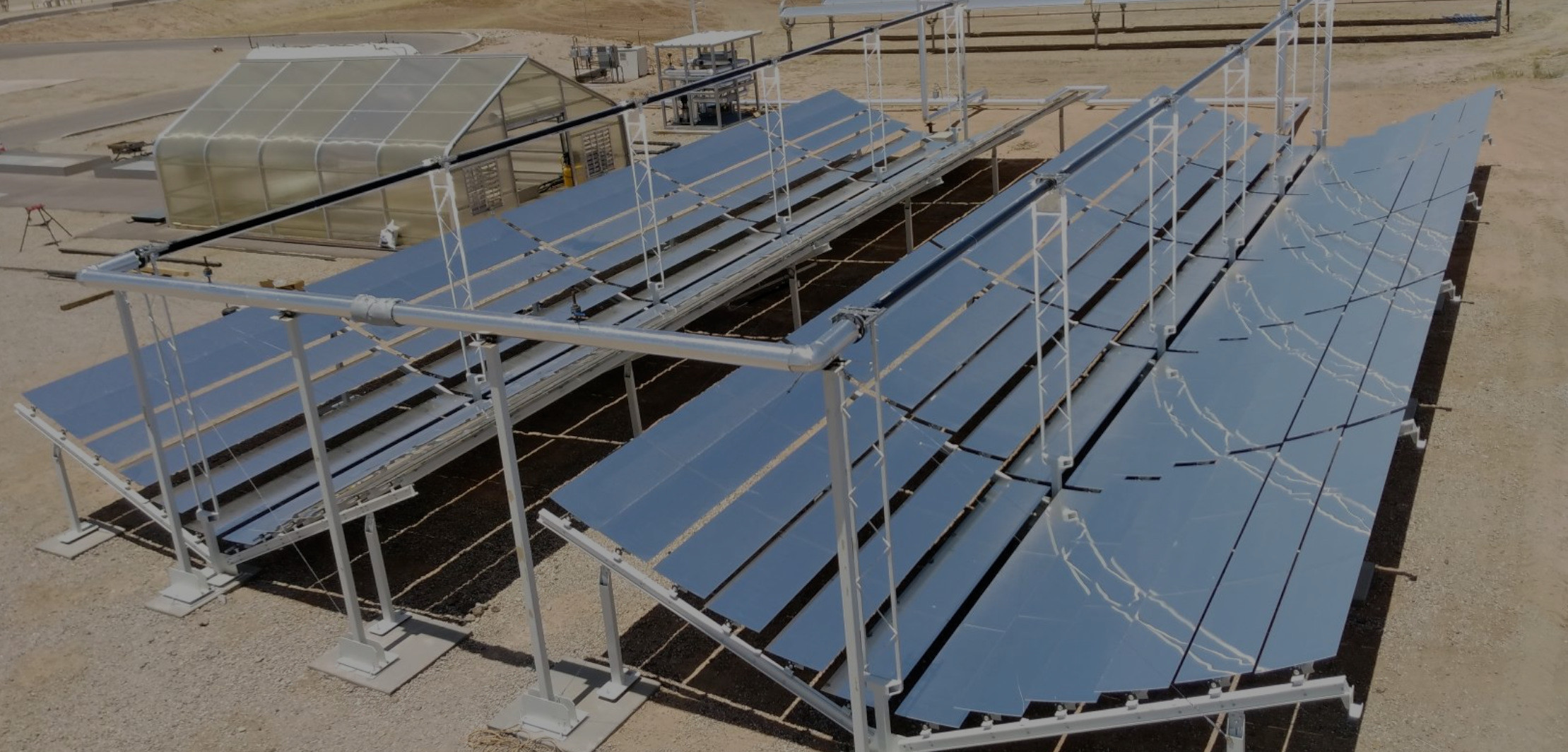

Rioglass Solar is an international renewable energy company with more than 15 years of experience in the solar power industry. Rioglass Solar, founded in 2007, helps customers all over the world to capture and harness the sun’s energy for renewable electricity production through specialised O&M services, manufacturing of key components, and C&I PV generation.

Services for renewable plants

Rioglass Solar is committed to providing the maximum added value to its customers. That’s why we’ve developed a wide range of specialised services for renewable plants, thanks to our highly qualified and experienced staff, and our capacity for innovation. These services include operation and maintenance, as well as monitoring, analysing and optimising the performance of renewable plants. These specialised services are based on Rioglass Solar's many years of experience in the design and manufacture of key components for solar power plants. Services include:

- 1. Operation and maintenance services for photovoltaic and solar-thermal plants

- 2. Specialised services for PV plants during implementation, the warranty period and commercial operation

- 3. Specialised services for solar thermal plants

- 4. Characterisation of main equipment in electrical installations

- 5. Consultancy services, profiling of main components and plant status, and due-diligence reports for asset sale and purchase processes

1. OPERATION AND MAINTENANCE SERVICES FOR RENEWABLE ASSETS

Rioglass Solar performs conventional operation and maintenance (O&M) services for renewable assets, including real-time asset monitoring, preventive and predictive maintenance for main components, corrective maintenance and auxiliary services.

2. SPECIALISED SERVICES FOR PV PLANTS DURING IMPLEMENTATION, THE WARRANTY PERIOD AND COMMERCIAL OPERATION.

These specialised services include the following:

- Thermographic analysis of PV modules, electrical panels, substations and power lines using drones

- I-V curve analysis for module and string performance analysis, and comparison with manufacturers' specifications

- Electroluminescence

- Module cleaning

3. SPECIALISED SERVICES FOR SOLAR THERMAL PLANTS

- Replacement of mirrors and receiver tubes including loop drainage, insulation work and certified welding

- Thermographic analysis for solar field profiling, including the condition of receiver pipes

- InFRReS® (Injection Feeding Receiver Recovery Services) - Argon injection into receiver tubes using technology protected by an exclusive patent licence

- Analysis of useful life of pipes using getter profiling

- Optical profiling of solar fields

- Pipeline inspection

- Solar field optimisation of parabolic trough collectors using mechanical alignment of pipes, modules and inclinometer calibration

- Heliostat solar field optimisation using mirror, heliostat and facet shaping

- Mechanical maintenance and assembly

- Insulation of main equipment: turbines, tanks, pipes, etc.

- RioH2Meter® - Real-time monitoring of hydrogen in receiver pipes for profiling of pipe condition and definition of mitigating measures.

- Replacement of rotary joints and other mechanical actions

- Operation and maintenance of water treatment plants

- Thermographic profiling of storage tanks, pipelines and other main equipment

- Ultrasonic leak detection

- Profiling of vibrations in rotating equipment

- Skilled labour

- Manufacture or reconditioning of special components

4. PROFILING OF MAIN EQUIPMENT IN ELECTRICAL INSTALLATIONS

Whether by means of thermography and ultrasound, by drone or on foot, Rioglass Solar carries out complete profiling of the main electrical installation equipment, such as substations and lines.

5. TECHNICAL CONSULTANCY SERVICES, PLANT CONDITION CERTIFICATION AND DUE-DILIGENCE REPORTS FOR ASSET SALE AND PURCHASE PROCESSES

Rioglass Solar provides technical consultancy services, specialising in problems related to solar thermal fields, photovoltaic module fields and plant profile studies.

If you have complex, unsolved problems at your solar plant: Challenge us to come up with solutions!

REFERENCES

Operation and maintenance of a 200 MW solar thermal platform in Extremadura

Operation and maintenance of a 100 MW solar thermal platform in Seville

Operation and maintenance of 1 MW PV plant in Seville

Optimisation of heliostat solar field in Seville

InFRReS® Argon Injection in more than 13.000 tubes across the world

RioH2Meter® installed in 2 solar thermal plants in the USA

Inspection of piping in plants with a total capacity of more than 600 MW

Useful Information

Here, you can have useful information...